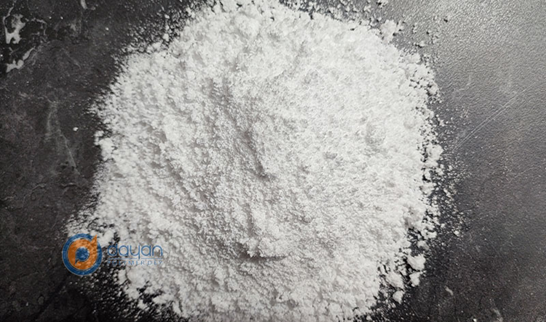

Styrene Butadiene Styrene (SBS) compounds

SBS is a three-block elastomeric thermoplastic composed of styrene and butadiene. SBS behaves like elastomers, originating from butadiene blocks (rubbery section), and has a process similar to plastics, originating from styrene blocks (hard section).

SBS is produced by living anionic polymerization with styrene and butadiene in the reactor. SBS behave like elastomeric rubbers at room temperature, but after heating, they can be processed like plastics.

SBS provides excellent impact strength and is used for compounding in various applications such as bitumen and asphalt modifications, adhesives, shoe soles, etc.

According to the desired application and properties, some materials are added to SBS, forming the SBS

compound. A versatile hardness range can be processed by SBS compounding.

SBS

The following ingredients are added to the SBS compound for use in shoe soles:

- Plasticizer softens the rubber and improves the melt flow properties.

- Polystyrene resins harden the rubber and raise the modulus.

- Fillers are added to cheapen and harden the product.

- Stabilizers reduce breakdown due to heat and light.

- Pigments impart the required color.

Processing The components are first weighed out and then the following sequence of operation is followed:

- Cold premixing

- Hot mixing

- Milling

- Extrusion

- Pelletizing

- Injection molding of the compound

General advantages of SBS compounds:

- SBS compounds are low-density compounds.

- SBS compounds generally have good resistance to flex cracking which improves as the temperature is reduced.

- SBS compounds have a very good slip resistance which decreases with increasing hardness.

- SBS compounds have a low processing cost and faster production.

- SBS compounds have high resilience.

The most important advantages of SBS compounds in comparison to other styrenic thermoplastic compounds are:

- Easy processing

- low price

- Short process time

- High thermal stability

- Good performance against UV

- Wide range of hardness

- Good mechanical properties

- High elongation at break

- Plastics processing equipment can be used for processing

- Recyclable

The most important disadvantages of SBS compounds in comparison to styrenic thermoplastic compounds:

- SBS compounds have poor wear resistance.

- They are poorly resistant to oils and solvents.

- Smooth molded surfaces are difficult to obtain.

- Adhesion was a serious weakness of the thermoplastic rubber, which is improved by a halogenation process that needs to be carried out with extreme accuracy in the bonding process.

The most important applications of SBS compounds are:

- Adhesives, sealants, and coatings

- Alternative to vulcanized rubber

- shoe industry (such as shoe soles)

- Food packaging

- Curtain and furniture industries

- Impact modifier for compounding

- Viscosity index increaser for lubricating oils